Company

-

DERIVADOS DEL MOTOR S.L.U. s a 100% family-owned company, founded in 1972 with its headquarters in Banyoles (Girona). Its main function is the manufacture of welded mechano structures.

-

DM activity is mainly directed to the OEM supply for the sectors of motorcycle, bicycle,metal furniture, agricultural machinery, etca

-

Present

Present

-

Looking to the future

Looking to the future

-

History

History

-

Our objetive

our objetive

-

Our values

Our values

-

Quality

Quality

-

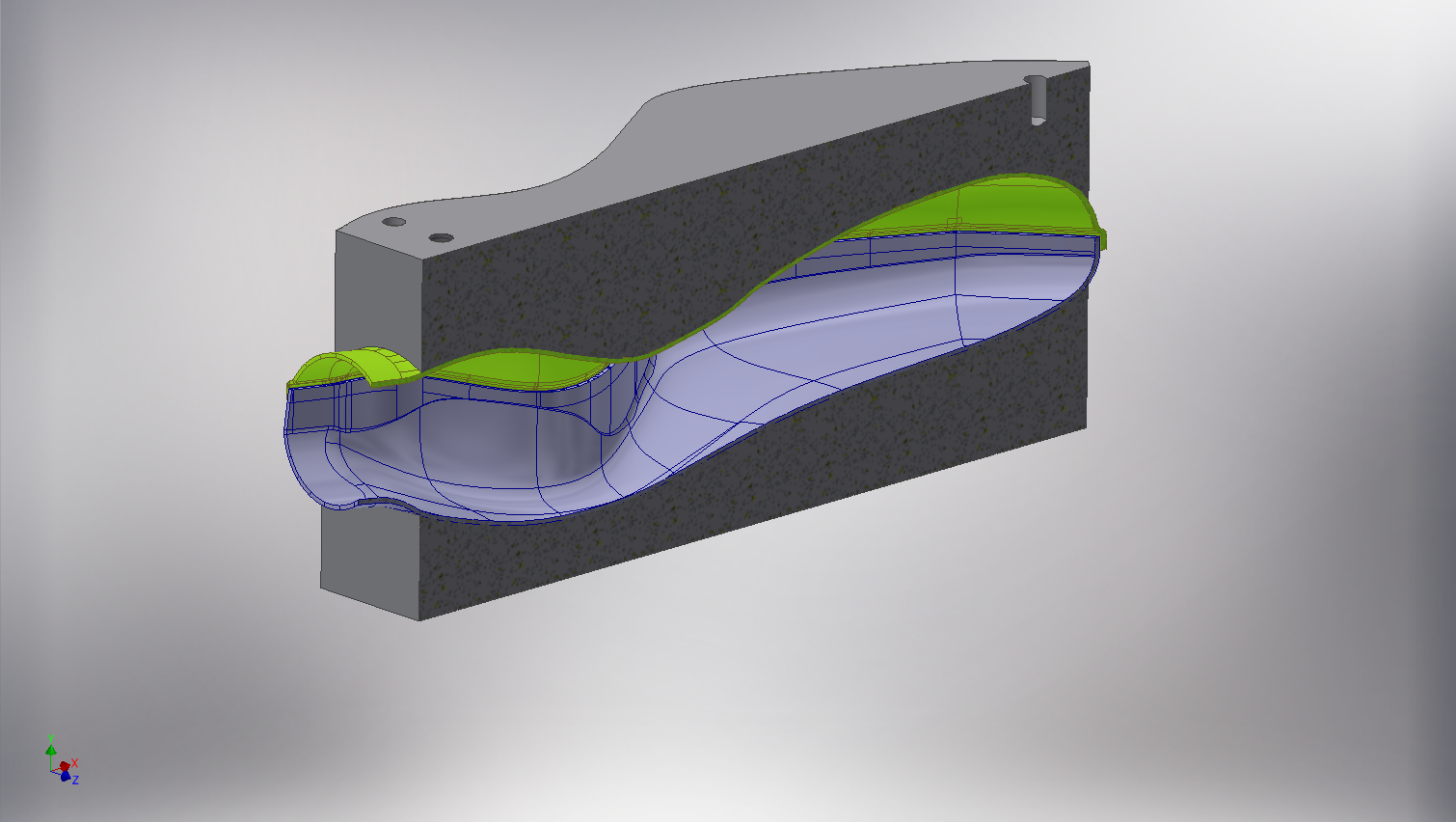

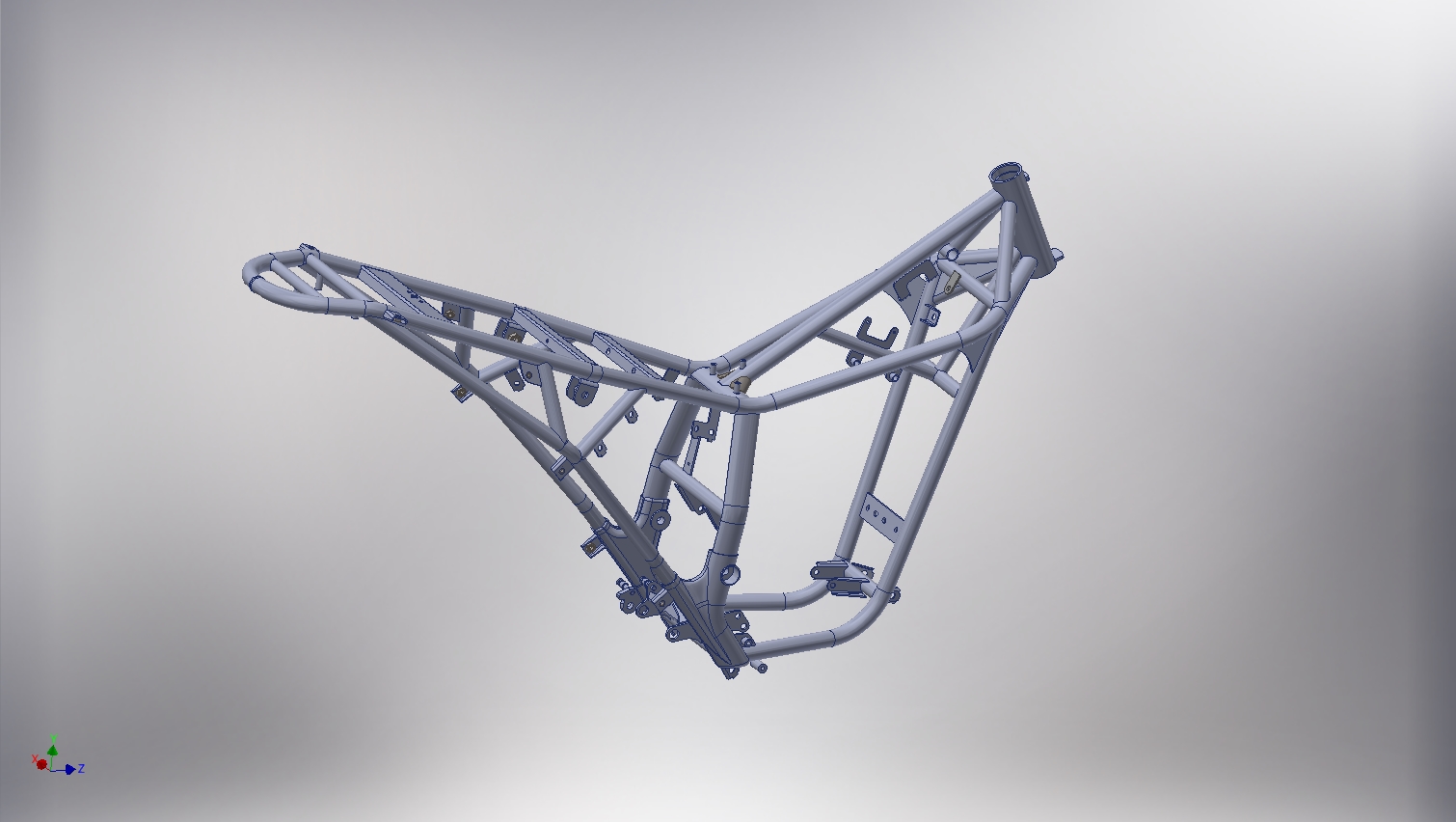

Technical Department (R & D)

Technical Department (R & D)

-

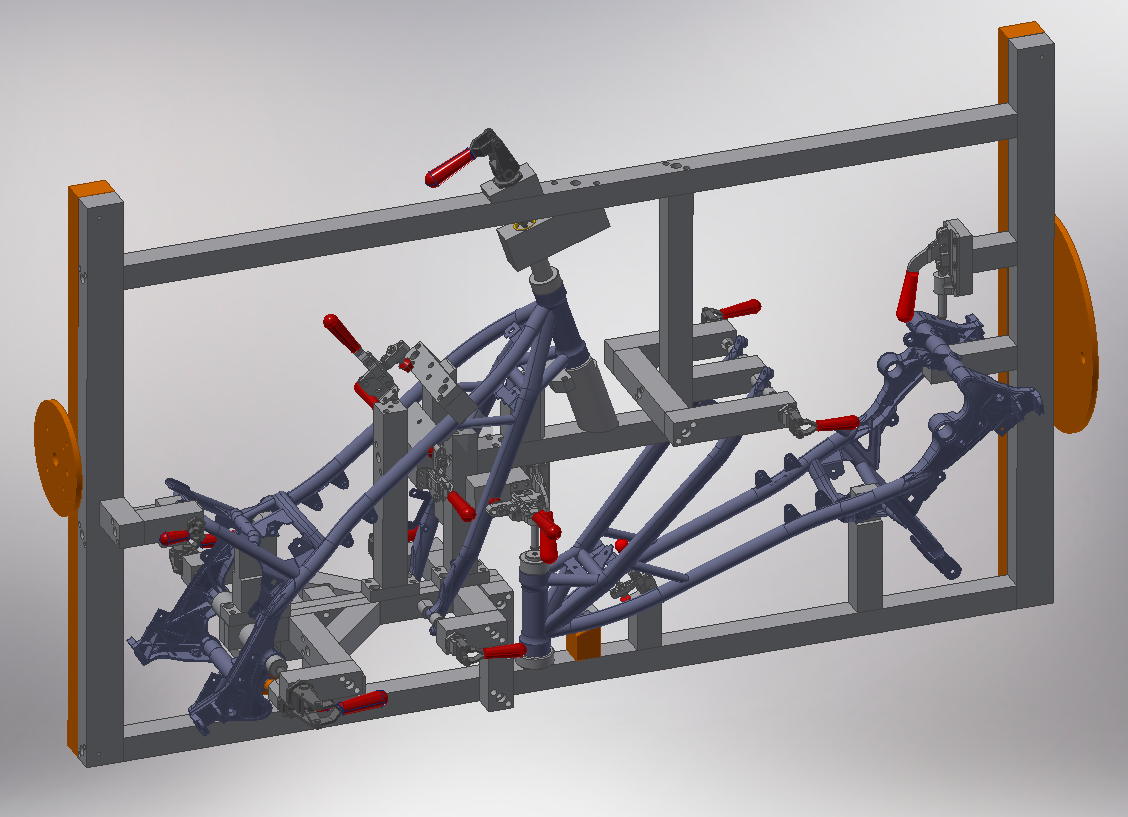

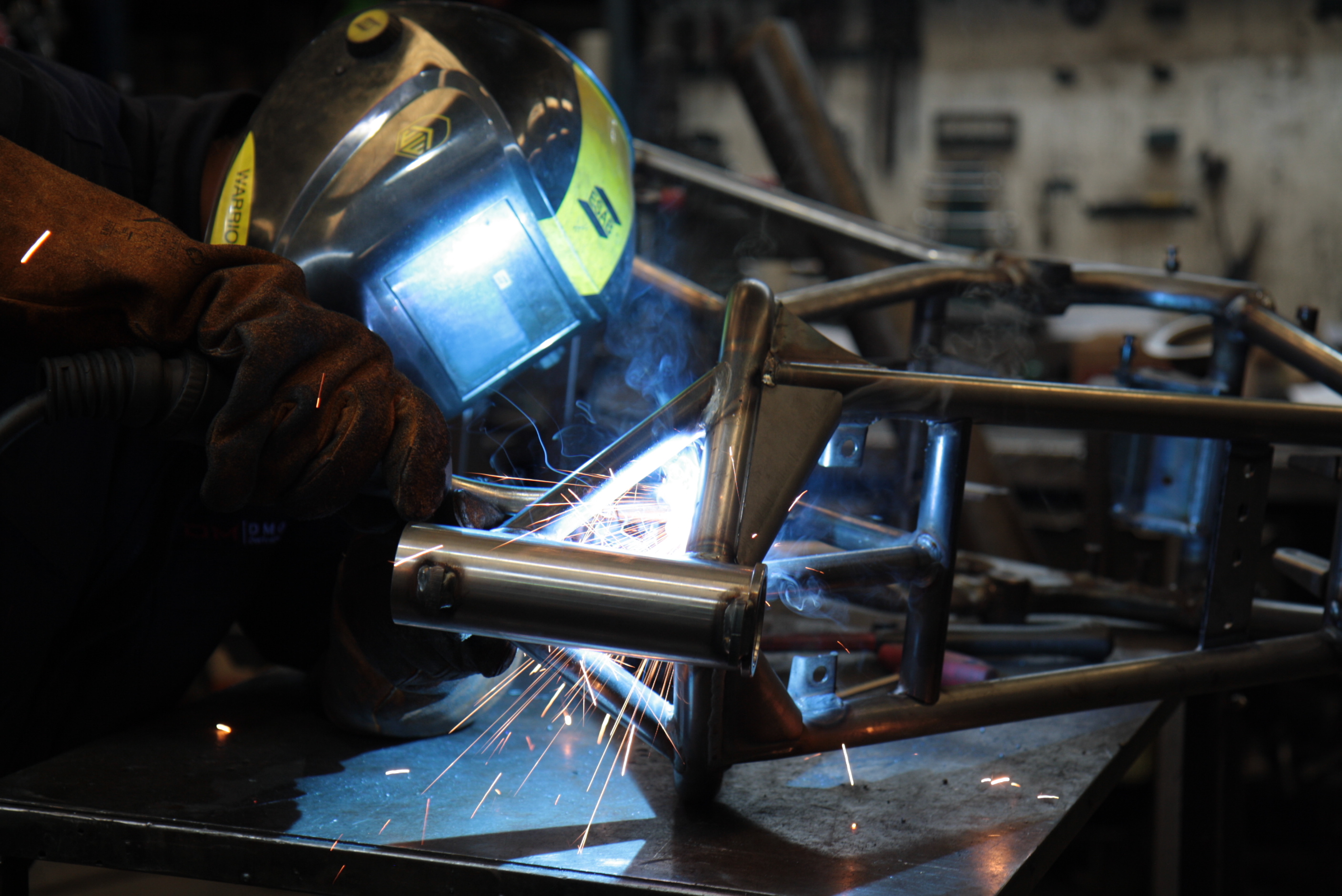

Operations Department

Operations Department

6000 M2

78 workers

+ 25% of our manufacturing is for the electric mobility sector

We export 70%

Getting ISO certificates and total integration of the ERP system

Be a reference provider in the sector

Diversification towards new sectors

Continuous training of the human team.

1972

1972

- Derivados del Motor is born in Fontcuberta, Girona, as a manufacturer of leaks under Jorman’s brand

1973

1973

- Start exporting at European level

1975

1975

- Derbi provider, relationship that continues to this day.

- Derbi is followed by Hercules, KTM, Peugeot, Honda …

1982

1982

- The figure of 25 workers is reached

1988

1988

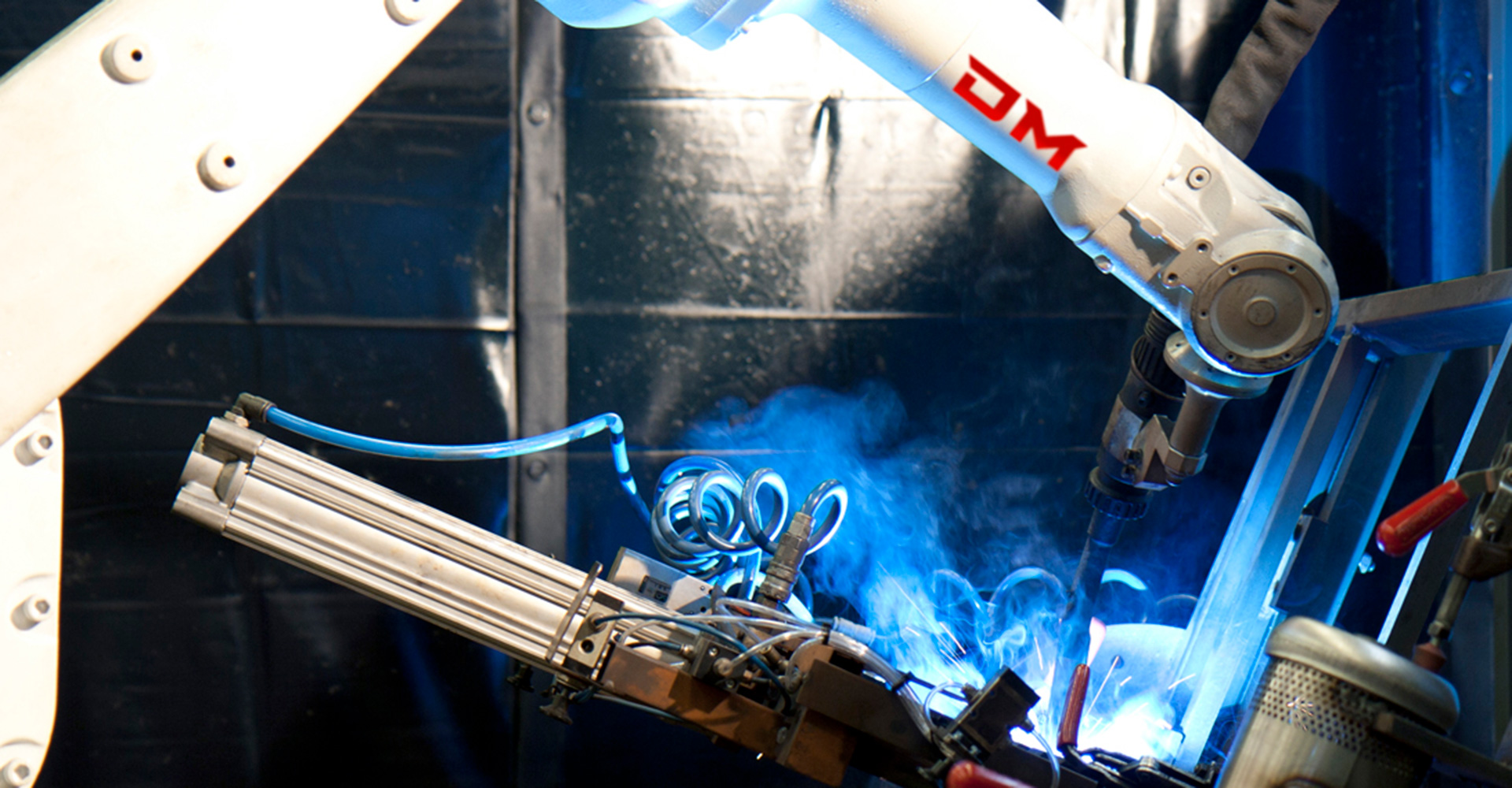

Incorporation of the first welding robot

2001

2001

- Start the welding of chassis and swingarms for motorcycles

2006

2006

- Born None.

- Transfer to a new warehouse in Banyoles, Girona, with more than 6000 m2

2017

2017

- International company with more than 65 workers.

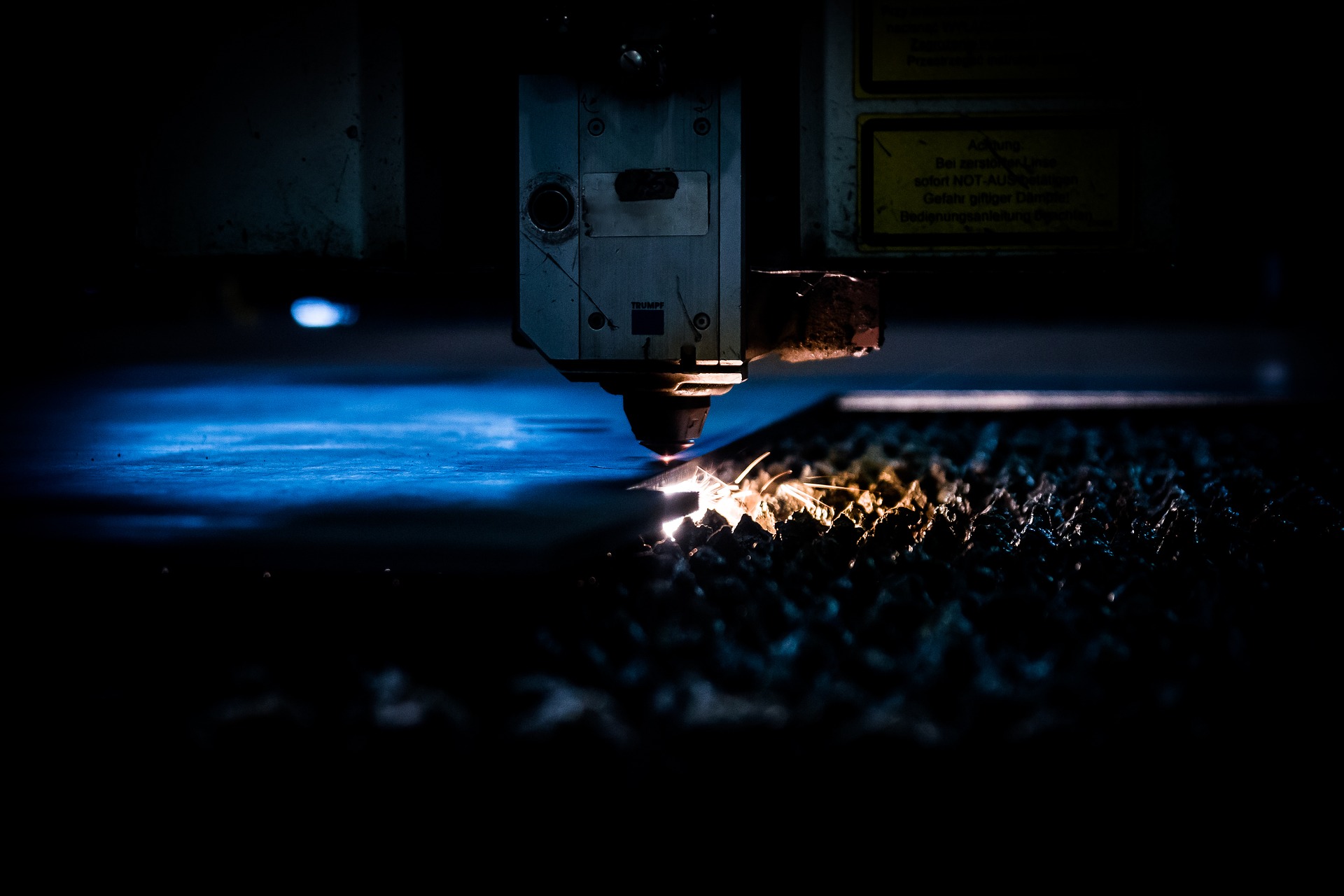

The Dept. of Operations is our area in charge of planning and organizing from the supply chain.

Maximize all available resources and achieve constant and direct communication with all the other functions of the organization, to achieve the expectations of the company as a whole.

The Dept. of Operations is the one that manages the different production sections of our company: